Wire handles come in several forms and sizes and are shaped and configured to fit the requirements of the load that a bucket, pail, or container holds. For heavy loads, wire handles are made of highly resilient metals, such as galvanized steel, carbon steel, and mild steel. Read More…

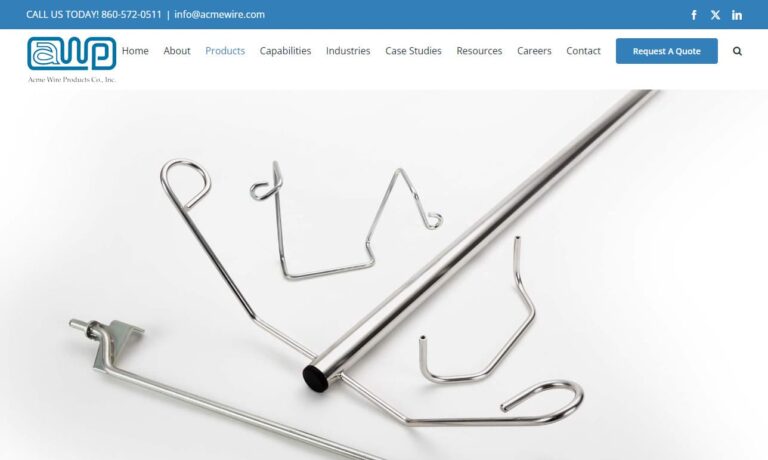

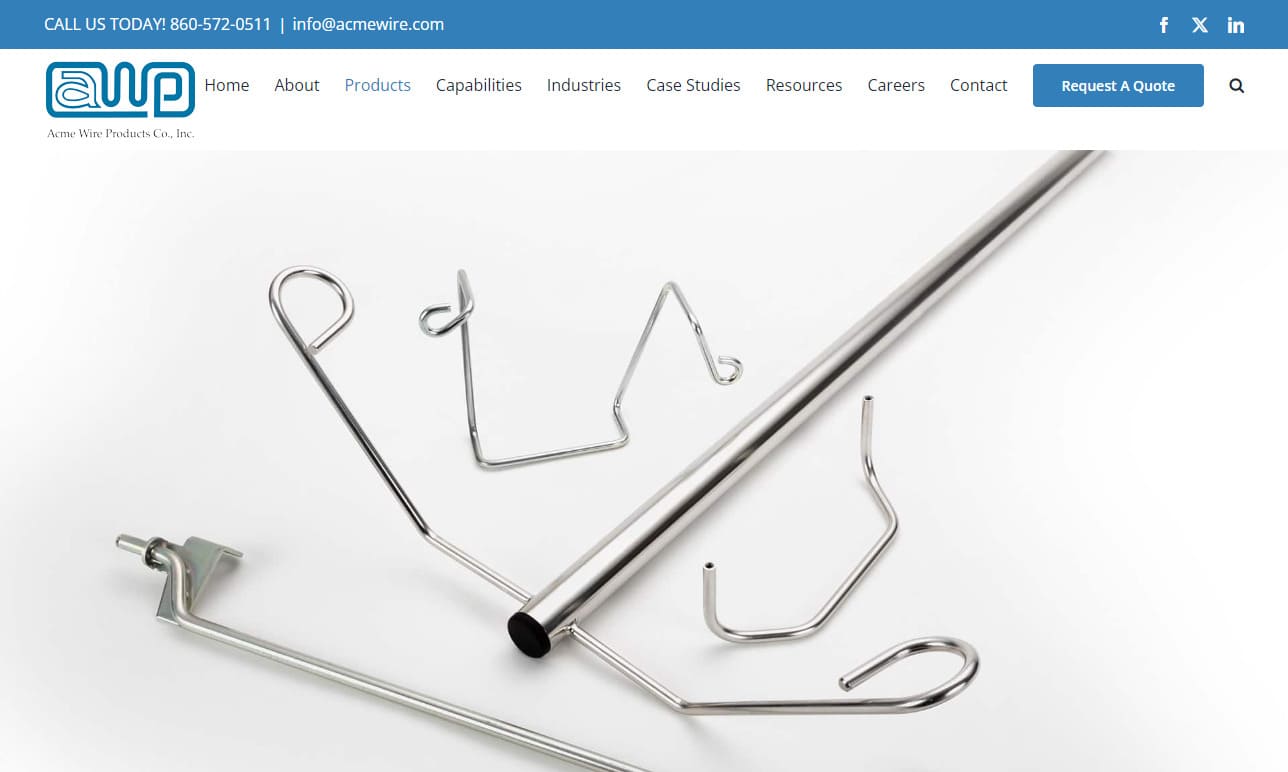

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

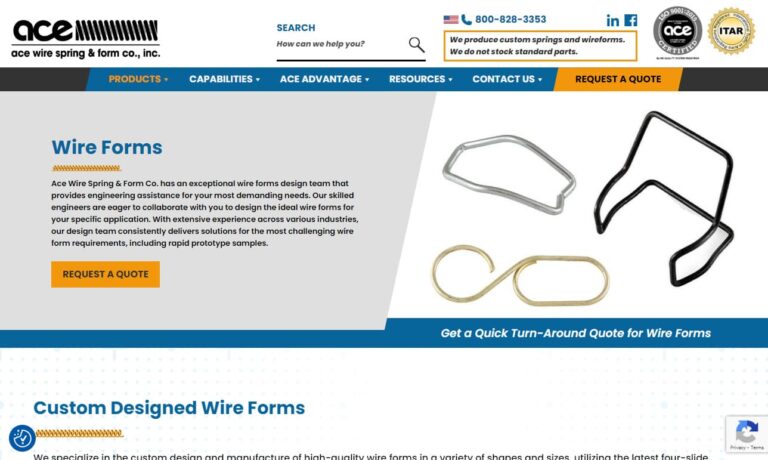

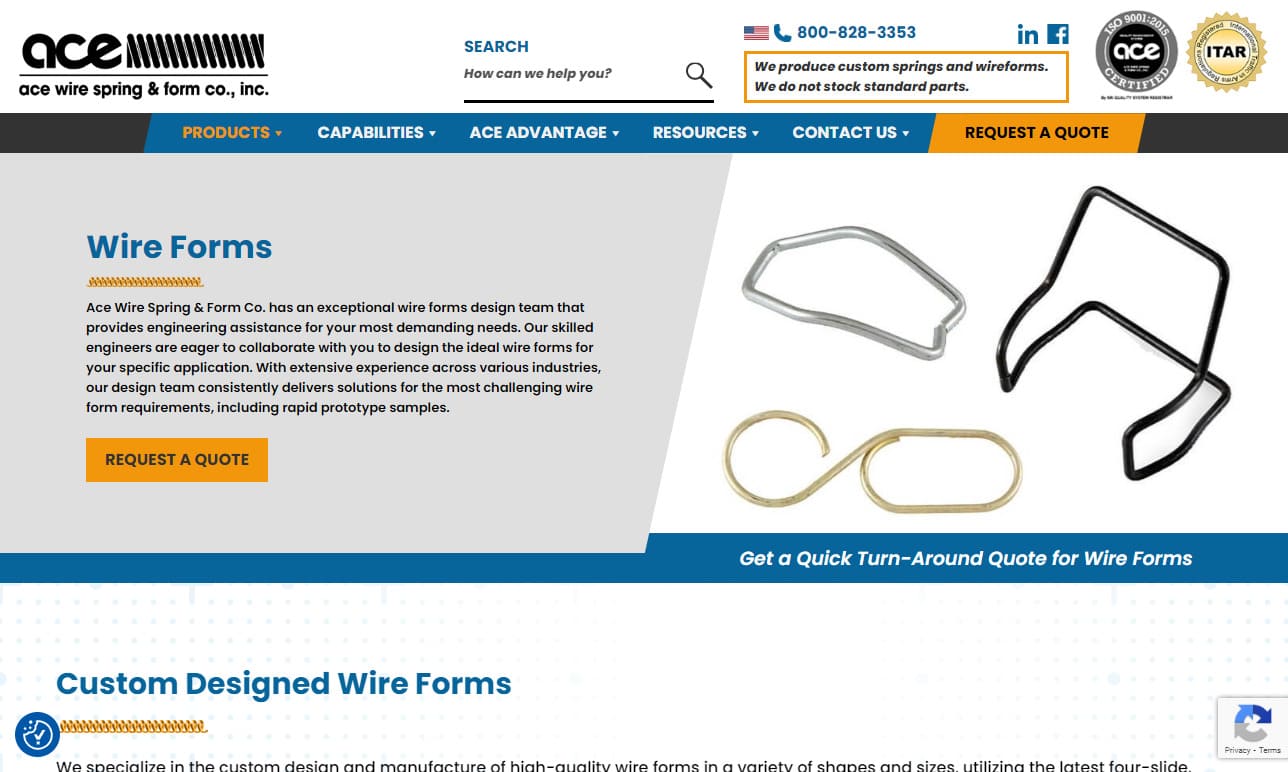

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Illini Wire Works, Inc. stands as a distinguished leader in the realm of wire fabrication, providing unparalleled expertise in crafting custom wire forms and industrial fan guards. With a heritage of precision and innovation, we have become a trusted partner for clients seeking high-quality wire solutions tailored to their unique specifications. Illini Wire Works excels in the art of custom wire...

At Royal Coil, Inc., we specialize in crafting high-quality wire forms tailored to meet the unique demands of our customers. Our expertise spans a wide range of industries, enabling us to deliver precision-engineered solutions that excel in both functionality and durability. With advanced manufacturing capabilities, we transform wire into complex and reliable components that support a variety of...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At Katy Spring & Mfg., Inc., we specialize in the design and production of high-quality wire forms tailored to meet the diverse needs of our customers. Our expertise lies in transforming raw materials into complex, precision-engineered components that support a wide range of industries. By combining innovative technology with a deep understanding of our customers’ requirements, we deliver wire...

More Wire Handle Manufacturers

They are shaped to be attached to containers by being bent or twisted at the end of their wires such that the ends fit into the ears or mounts of a container. There is a wide range of types, kinds, shapes, and configurations of wire handles with some types having plastic, wood, or rubber grips added.

What are Wire Handles?

Wire handles are a very common form of handle and are found on paint cans, waste buckets, tool buckets, cooking pots, pails, and other forms of containers. They are an inexpensive but strong tool that helps move cylindrical containers from one location to another. Wire handles are a dependable and resilient tool that make the carrying of pails and buckets easy and convenient.

The term wire handle covers a long list of handles that come in different forms to fit the needs of a round cylindrical container. Some containers require one wire handle such as a bail handle that is attached to mounts or ears on the sides of a cast iron cooking pot. This particular configuration is quite common and is found on several buckets or pails with different types of ears or fixed points of connection.

Wire handles can be curved in an arc, curved from the sides of a container and flat at the top, or come in pairs. Their width and length are determined by the diameter of the bucket, pail, or can they hold. Wire handles have been used for many years to hold cooking pots over a fire. In those instances, the handles were similar to a metal rod that had been bent.

Wire Handle Metals

The types of metals used to make wire handles vary depending on the load they will carry. The preference is usually galvanized steel due to its strength, durability, corrosion resistance, and longevity. Galvanized carbon steel is the most widely used due to its low cost, corrosion resistance, and exceptional strength. Alloyed metals, such as copper, aluminum, or nickel, which are easy to shape and form into wire, are used for lighter loads or aesthetic purposes.

The deciding factor for all forms of wire handles is their durability and dependability, especially in cases of heavy loads where failure can be harmful or dangerous. When a particular load is especially heavy, two wire handles may be used with a grip. Stainless steel is used to increase the durability, corrosion resistance, and strength of wire handles, which is especially true in conditions where hygiene, cleanliness, and a sanitary environment are required.

How Wire Handles are Made

Wire handles are manufactured using a metal forming process completed by a single machine. The machine is fed wire from a huge spool of wire. Metal wire is formed when heated metal is pulled or pushed through a die that has the precise diameter of the wire. The thickness of the wire can be adjusted and changed according to the type of wire handle.

Since the wire is fed from a large wound spool, it has to go through a straightening process prior to being fed into the forming machine. The straightener consists of several rollers that apply pressure to the top and sides of the wire. The function of the straightener is to remove deformations, crooks, flaws, and other imperfections to give the wire a round shape. In order for wire handles to be shaped appropriately, the wire must be fed to the shaping press in ideal conditions. Variations in the shape of the wire can damage the final wire handles or the shaping machine.

The process of wire forming of wire handles begins with a huge spool of wire that sends wire to the wire straightener. The straightener uses its series of rollers to correct any errors in the wire and flatten it such that it moves smoothly to the press that forms the wire handle. As the wire is fed into the press, it is cut to the length of the handle and pressed by force against a die that has the end shape of the wire handle. Once the handle is shaped, it is released into a collector, basket, or other form of container.

Additional features can be added to wire handles to adjust it to fit the type of bucket, pail, or pot to which it will be attached. One of the addons for wire handles is grippers that are place over the top of the wire to make it more comfortable to handle the wire handle. The attachment of grippers can take place prior to the deformation of the wire or after deformation.

Wire Handle Grips

As with wire handles, wire handle grips take several different forms depending on the material from which they are made, their size, and the type of wire of the wire handle. They are made from plastics, rubber, and wood. The shape of wire handle grips is that of a tube or cylinder that is a few inches long with a hole down the center of the cylinder that fits around the wire of the wire handle. They are positioned at the top middle of a wire handle and can be tightly attached without any slippage or be loosely attached such that they float around the wire handle.

The use of grips with wire handles is dependent on the weight of the load of the container, which can vary from a few pounds up to a couple hundred pounds depending on the application. As the weight of the load increases, the material of the grip becomes more sturdy and durable in order to prevent the grip from cracking or breaking. In the majority of cases, grips are used with heavy loads and seldom with small loads. Paint retailers use paper grips for their products to make carrying a bucket of paint easier.

Conclusion

In many cases, people seldom pay attention to wire handles unless they underperform or break. In industrial applications, wire handles are carefully planned, engineered, and designed for safety and prevention of material losses. Wire selection, handle shape and form, and wire handle attachment are key factors in the design and manufacture of wire handles, which are a vital tool in material handling.

Cold Headed Parts

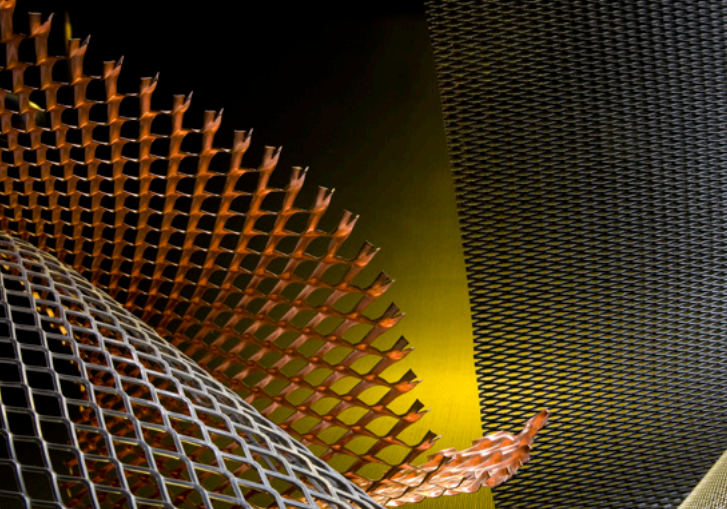

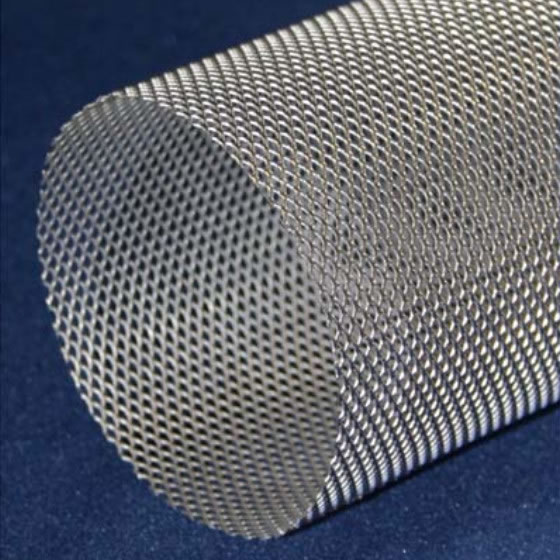

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services