Wire forms are very flexible, enabling them to be altered into an extensive number of shapes and particular configurations. When a wire is taken from a blank length or spooled coil, and bent into specific forms it is called wire forming. One example of an industry that benefits from wire forming processes is the retail and commercial business, which uses wire forming for product placement applications such as customized wire displays, shelving, hooks, baskets, springs, clips, material handling solutions, dividers, and so much more. Read More…

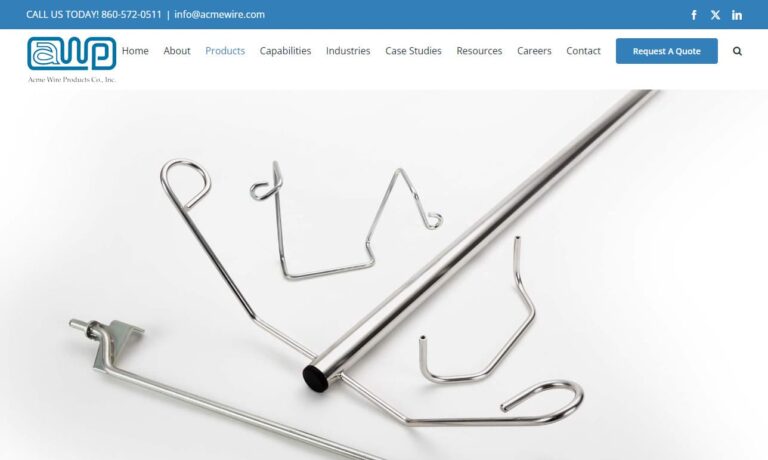

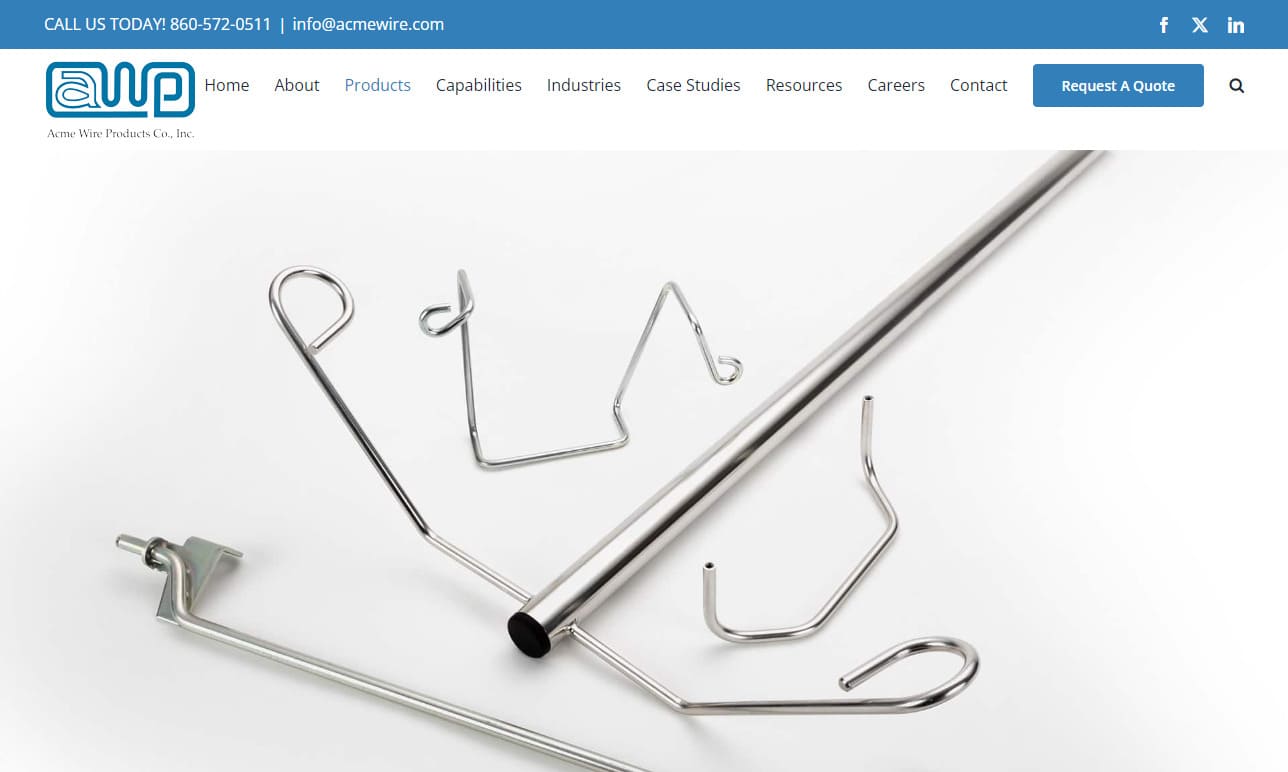

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

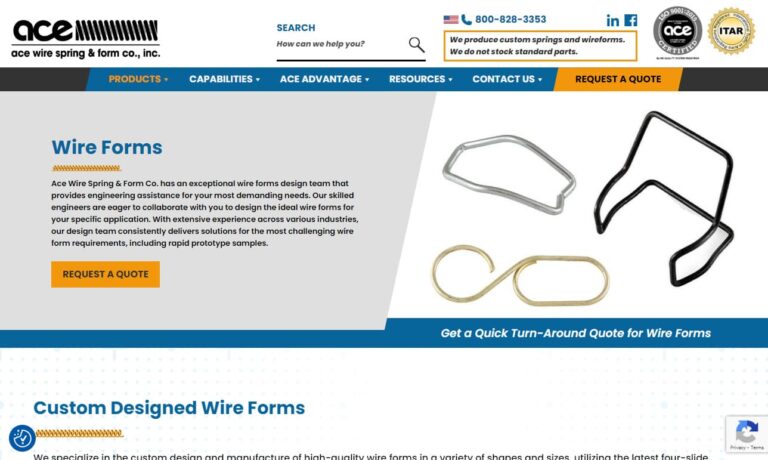

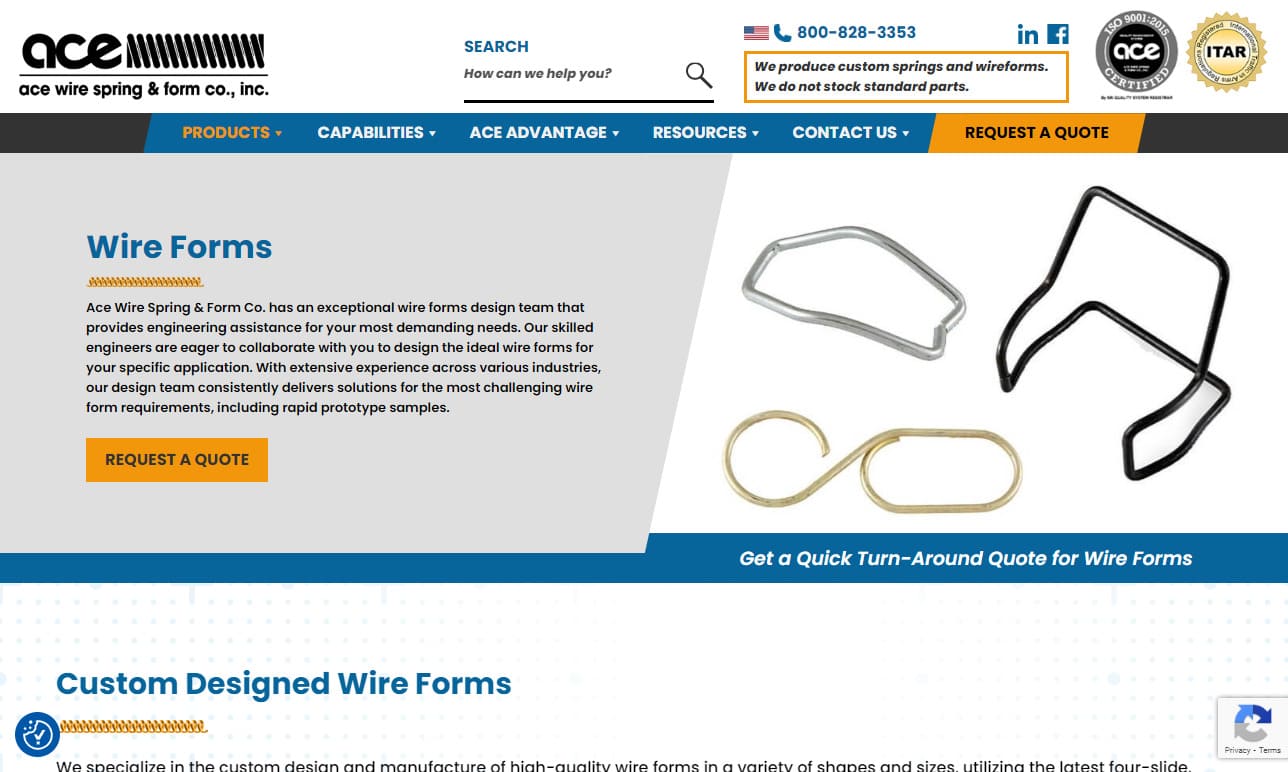

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Illini Wire Works, Inc. stands as a distinguished leader in the realm of wire fabrication, providing unparalleled expertise in crafting custom wire forms and industrial fan guards. With a heritage of precision and innovation, we have become a trusted partner for clients seeking high-quality wire solutions tailored to their unique specifications. Illini Wire Works excels in the art of custom wire...

At Royal Coil, Inc., we specialize in crafting high-quality wire forms tailored to meet the unique demands of our customers. Our expertise spans a wide range of industries, enabling us to deliver precision-engineered solutions that excel in both functionality and durability. With advanced manufacturing capabilities, we transform wire into complex and reliable components that support a variety of...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At Katy Spring & Mfg., Inc., we specialize in the design and production of high-quality wire forms tailored to meet the diverse needs of our customers. Our expertise lies in transforming raw materials into complex, precision-engineered components that support a wide range of industries. By combining innovative technology with a deep understanding of our customers’ requirements, we deliver wire...

More Wire Forming Manufacturers

A wire form can be coiled, angled, cut, or bent into all different ways, making them perfect for custom-made projects. Whether formed into small springs for machine pieces, to big chains which carry heavy things, wire forming is beneficial to many applications.

The Cost of Wire Forming

Wire forming costs are dependent on the parts which go into developing the product and its use. Factors, like wire material, labor, wire volume, application of machines, and transporting expenses of formed wires, all add to the total price of wire forms.

Different material types also differ in cost. For instance, some material will be more costly than others because they can handle higher temperatures. When determining the cost of wire forms it is important to consult an expert. They can aid in determining the best wire forms for products based on their use and environment. Experts can provide accurate estimates of the overall costs.

The Benefits of Using Wire Forms

Choosing the correct wire forms can improve efficiency, reduce expenses from damaged products, and decrease probabilities of employee injury.

Improved Efficiency

High-quality wire forming machines can provide manufacturing factories with the proper tools to finish operations efficiently and quickly, boosting productivity.

Reduced Expenses

High-quality wire forms are made to last years of frequent use without danger of breaking. Broken machines result in downtimes, which may add expense and damage to products. High- quality equipment decreases the risk of extra costs because of faulty manufacturing.

Better Employee Safety

Proper wire-forming products will help better employee safety. Cheap wire forms will break, damage nearby machines and injure employees. By buying high-quality wire forms, their structural strength can be relied on to handle released stresses.

The Biggest Challenge in Manufacturing a Wire Form?

The short answer is that it depends. Every client has distinctive needs. Due to this, any given client may require vastly distinct wire forms for their certain washing and baskets handling parts. From choosing the proper steel grade, coatings, welding techniques, and particular shaping needs for a given washing basket part, the variations for the washing basket’s design can go on and on.In some tasks, forming the bend in the wire just right may be the most challenging aspect of producing a wire form. Making the essential welds could be the hardest task to do in others.

It may be said that acquiring the proper design for wire forms to meet the requirements of a specific operation is the most challenging facet of the process. However, with the appropriate machinery and a skilled, well-trained worker who knows how to configure them in the controls, this is a task which can be consistently overcome.

For instance, piercing steel wire is one of the more difficult operations in wire forming. The procedure involves making a small opening on a piece of steel wire to allow another object to be run through it. This can be well seen in steel wire baskets meant to be attached on a peg wall or corkboard. Some of the wires might need to be perforated to allow screws, nails, or other fastening parts to be used to join the basket onto the other surface.

Since the steel wire to be punctured is commonly very solid and small, it needs careful preparation and great force, or else the steel wires may be deformed. This wire forming challenge may be overcome by utilizing a high tonnage steel press to perforate steel wires without needing to heat it up first.

How to Choose the Appropriate Wire Forming Products

Choosing custom-made, wire-forming products enables engineers to produce wire forms which fit unique specifications. Though stock wire-form products are mass produced and hence not made to accommodate a customer’s specific needs, custom-made wire forms may feature designs which are optimized carefully to a customer’s applications, like meeting parts-finishing processes. Custom wire-formed products may be designed particularly with specialized wires, inserts, or other special features depending on the need.

Additionally, custom wire-formed products are often made to withstand the pressures of multiple kinds of parts-finishing processes and, so, provide increased durability in contrast to stock wire forms. The right wire forms may save a manufacturing business money, time, material, and labor on production processes in comparison to stock products.

Choosing the Proper Wire Forming Company

To make sure you have the most positive outcome when selecting a wire-forming company, it is important to compare at least 4 companies using our wire forming directory. Each wire-forming company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each wire-forming company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple wire-forming companies with the same quote.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services