This process will help you find a wire form parts manufacturer who has experience working with applications that are similar to your own and will be able to suggest improvements in material, process, or secondary services your final product may need after the initial wire forming process has been completed. Read More…

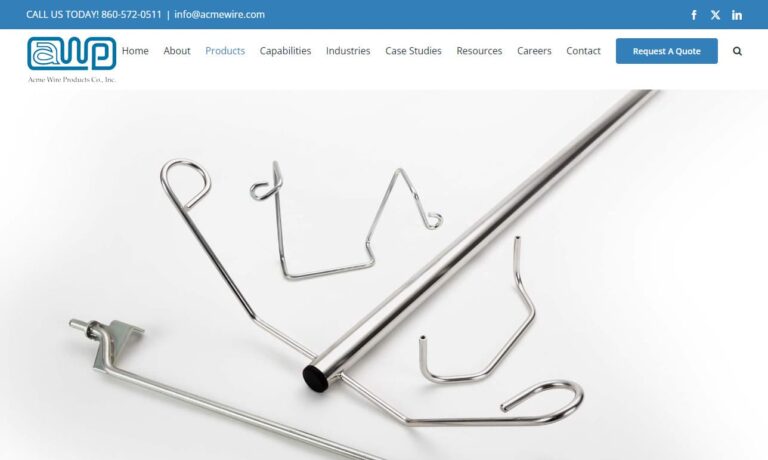

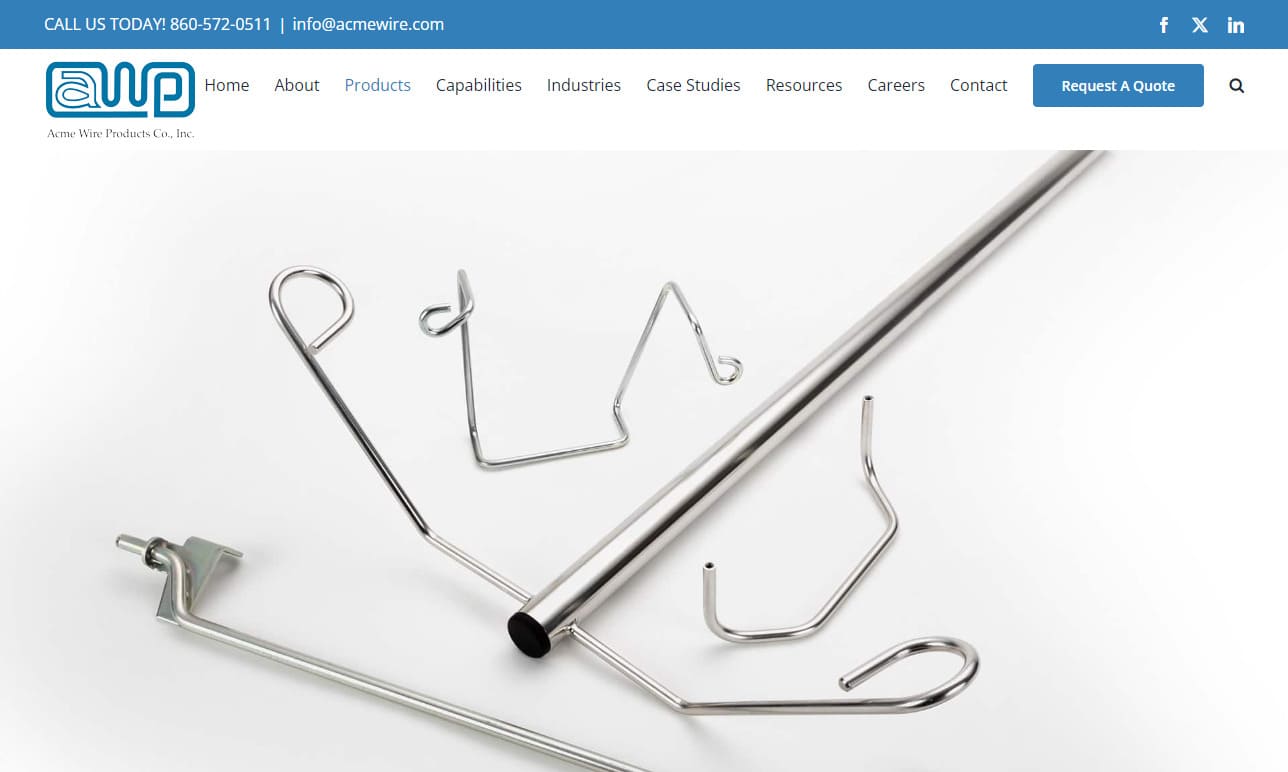

Acme Wire Products provides close tolerance wire fabrications using steel and stainless steel. Customized applications include a wide range of wire forms for many different applications. Acme works with wire from .050 to .500 diameter.

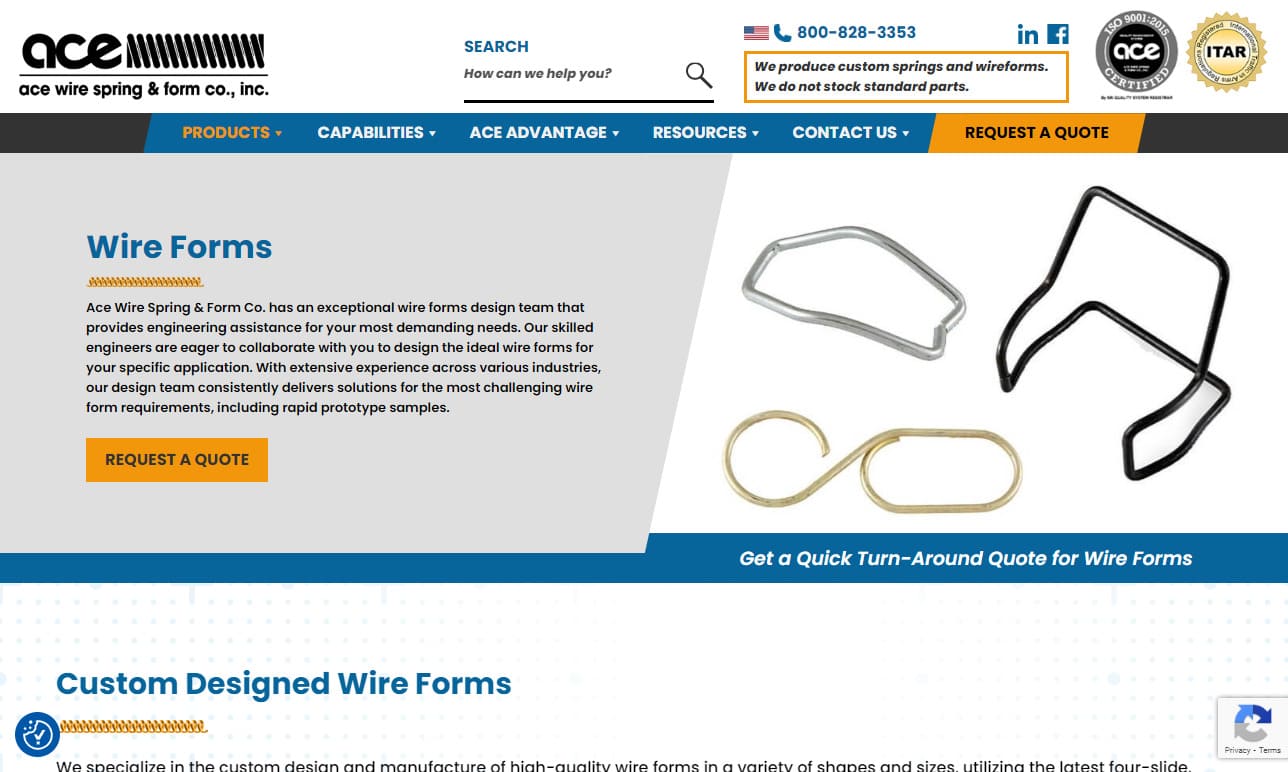

CUSTOM "Spring & Wire Form Specialists" - Ace Wire Spring & Form incorporates the latest CNC equipment technology to manufacture compression, extension, torsion springs, complex wire forms, and spring assemblies. We offer consistent quality, lower costs, on-time deliveries, and Design Engineering Assistance. Range from prototypes to long production runs - Family owned & operated since ...

Apex Spring & Stamping is a certified minority owned company that manufacturers springs, stampings, wire forms, clips, and fasteners. Our core industries include automotive, office furniture, medical, recreational, consumer goods, and appliances. We also specialize in value added assembly and prototyping. Our engineering team will ensure your part is both functional and cost-effective. IATF 16949 ...

Illini Wire Works, Inc. stands as a distinguished leader in the realm of wire fabrication, providing unparalleled expertise in crafting custom wire forms and industrial fan guards. With a heritage of precision and innovation, we have become a trusted partner for clients seeking high-quality wire solutions tailored to their unique specifications. Illini Wire Works excels in the art of custom wire...

At Royal Coil, Inc., we specialize in crafting high-quality wire forms tailored to meet the unique demands of our customers. Our expertise spans a wide range of industries, enabling us to deliver precision-engineered solutions that excel in both functionality and durability. With advanced manufacturing capabilities, we transform wire into complex and reliable components that support a variety of...

Here at Anderson Quality Spring Manufacturing, Inc., we take great pride in our position as a leading provider of wire forms, offering a comprehensive range of products, services, and capabilities to meet the diverse needs of our valued clientele. With our unwavering commitment to excellence and extensive expertise in wire forming technology, we stand ready to deliver innovative solutions that...

At Katy Spring & Mfg., Inc., we specialize in the design and production of high-quality wire forms tailored to meet the diverse needs of our customers. Our expertise lies in transforming raw materials into complex, precision-engineered components that support a wide range of industries. By combining innovative technology with a deep understanding of our customers’ requirements, we deliver wire...

More Wire Form Part Manufacturers

Finding a manufacturer that offers both the original manufacturing process and any secondary processes is a great way to improve your product while cutting down on the cost.

There are a wide range of forming processes available for wire form parts, some common processes you may be familiar with include: coil making, metal stamping, welding, and roll forming. The coil making process is commonly utilized to manufacture springs as it involves wrapping a wire around a metal blank which then forms a coil.

Roll forming on the other hand typically creates flat, shaped and round wire parts through the use of calendars and die punches that are able to shape the wire into the desired shape. One major process that you may not have thought of when it comes to wire form parts is the metal stamping process.

This process is used to manipulate wires in a precise fashion and to create different wire parts and products to customers' exact specifications. While there are a lot of different processes and types of wire forms out there, some are more common than others.

For example, wire shelving is one of the most common wire form product made, as they are relatively simple to manufacture and offer a high value product at the end of the process.

Whatever your needs may be, seek out an experienced wire form parts manufacturer to determine what is best for your unique application. They will be able to assist you in deciding on the best materials, design, and processes to use for your wire form parts.

Cold Headed Parts

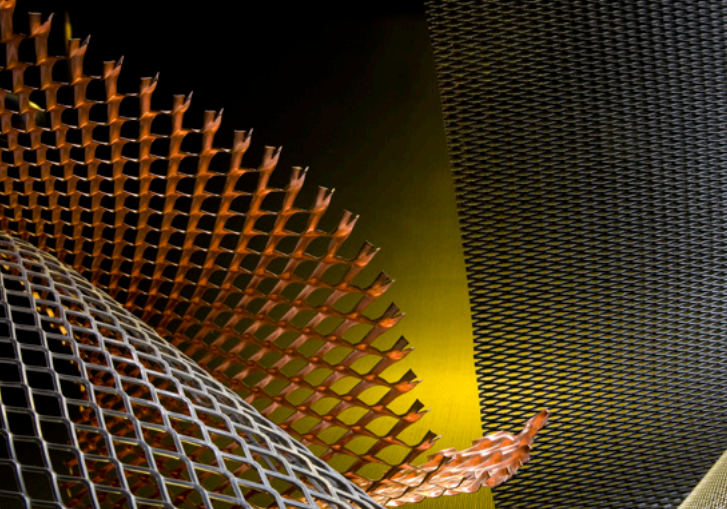

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

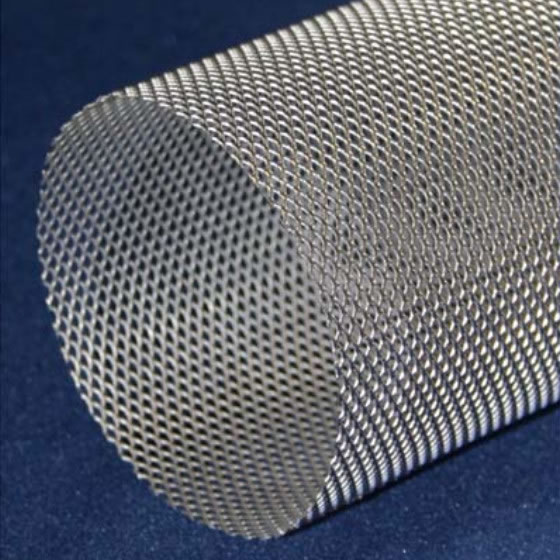

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services